- Hlau Txhaj Moulding MIM Qhov

- Hmoov metallurgy

- Tuag Casting

- 3D luam ntawv

Dab Neeg Nrog Cov Neeg Siv Khoom

MIM cov ntaub ntawv

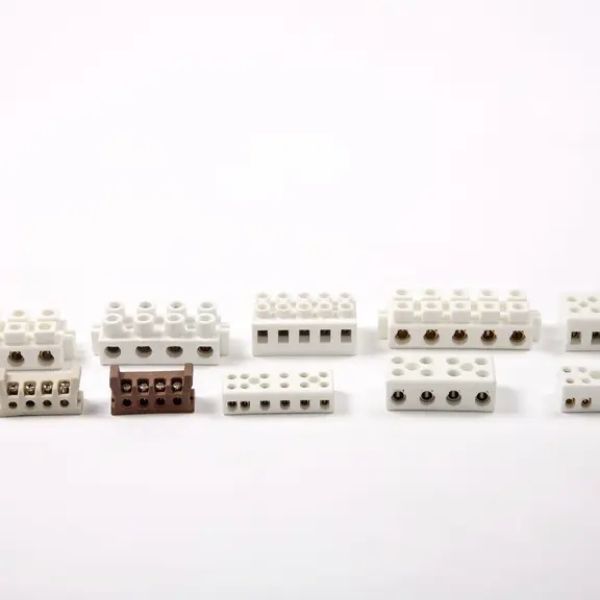

Cov ntaub ntawv siv tau rauHlau txhaj molding:

MIM txheej txheem siv tau rau ntau yam ntaub ntawv, suav nrog cov hlau tsis tshua muaj hlau, stainless hlau, cov cuab yeej hlau, npib tsib xee puag alloy, tungsten alloy, nyuaj alloy, titanium alloy, cov khoom sib nqus, Kovar alloy, zoo ceramics, thiab lwm yam.

Yam khoom siv hlau zoo li cas rau covMIM process:

1. MIM cov khoom hnyav feem ntau yog 0.2g - 200g.

2. Qhov projected cheeb tsam yog 100 square centimeters.

3. MIM qhov loj qhov tseeb tshaj 10MM yog ± 0.5%.

4. MIM qhov siab tshaj plaws phab ntsa thickness yog 10MM.

5. Yam tsawg kawg nkaus 0.2MM.

Table 1 Feem ntau siv MIM cov ntaub ntawv thiab lawv daim ntawv thov teb:

Khoom siv system | Alloy hom, muaj pes tsawg leeg | Daim ntawv thov teb |

Tsawg alloy steel | Fe-2Ni, Fe-8Ni | Ntau yam qauv ntawm tsheb, tshuab thiab lwm yam kev lag luam |

Stainless hlau | 316L, 17-4PH, 420, 440C Table 2 Cov khoom siv feem ntau siv MIM: | Cov cuab yeej kho mob, saib qhov chaw |

Hard alloy | WC- Co | Txhua yam riam, moos, watches |

ceramic | Al2O3, ZrO2, SiO2 | IT electronics, khoom siv txhua hnub, moos thiab watches |

Hnyav alloy | W-Ni-Fe, W-Ni-Cu, W-Cu | Kev lag luam tub rog, kev sib txuas lus, khoom siv txhua hnub |

Titanium alloy | Ti, Ti-6Al-4V | Kev kho mob thiab kev ua tub rog qhov chaw |

Cov khoom siv hlau nplaum | Fe, NdFeB, SmCo5, Fe-Si | Ntau yam khoom sib nqus |

Cov cuab yeej steel | CrMo4, M2 | Ntau yam cuab yeej |

Table 2 Cov khoom siv feem ntau siv MIM:

Khoom Siv Lub Npe | Alloy Composition (wt%) |

Qhov xwm txheej | Qhov ntom ρ (g / cm³) | UTS σ b (Mpa) | YS 0.2 (Mpa) | Elongation w (%) |

Hardness |

Tsawg Alloy Steel | |||||||

MIM 4600 (MIM 2200) | Ntawm 1.5 ~ 2.5% Mo 0.5% max Fe tshuav nyiaj li cas |

Sintered |

7.50 Nws |

290 |

125 |

40 |

45-65 HWB |

| MIM 4600 (Modeifed) (MIM 2700) | Ntawm 6.5 ~ 8.5% Mo 0.5% max Fe tshuav nyiaj li cas |

Sintered |

7.60 ib |

410 |

210 |

26 |

70-90 PAB |

|

MIM 4605 | Ni 1.5 ~ 2.5% Mo 0.2 ~ 0.5% C 0.4 ~ 0.6% Fe tshuav nyiaj li cas |

Sintered |

7.50 Nws |

415 |

255 |

15 |

65-85 HWB |

Thaum tshav kub kub kho | 7.50 Nws | 1655 | 1480 | 2 | 45-50 HRC | ||

|

MIM 4140 | Ntawm 0.75 ~ 1.25% Cr 0.75 ~ 1.25% Mon 0.75% max C 0.3 ~ 0.5% Fe tshuav nyiaj li cas |

Sintered |

7.50 Nws |

820 |

620 |

10 |

70 ~ 100 hli |

|

Thaum tshav kub kub kho |

7.50 Nws |

1400 |

820 |

5 |

45-45 HRC | ||

Stainless hlau | |||||||

|

ME SS316L | C 0.03% max Ni 10 ~ 14% Mo 2 ~ 3% Cr 18 ~ 20% Fe balance |

Sintered |

7.75 ib |

500 |

250 |

4 |

65-85 HWB |

|

MIM SS304 | C 0.08% max Ni 8 ~ 10% Cr 18 ~ 20% Fe balance |

Sintered |

7.65 ib |

480 |

270 |

35 |

65-85 HWB |

|

KUV SS420 | C 0.2 ~ 0.4% Cr 12 ~ 14% Fe balance | Thaum tshav kub kub kho |

7.40 Nws |

1310 |

11500 Nws |

6 |

40 ~ 45 HRC |

|

ME 17-4PH | C 0.07% max Cr 15.5 ~ 17.5% 3 ~ 5% Ni 3 ~ 5% Nb 0.15 ~ 0.45% Fe balance |

Sintered |

7.50 Nws |

900 |

730 ib |

6 |

20 ~ 28 HRC |

|

Thaum tshav kub kub kho |

7.50 Nws |

1185 ib |

1090 |

5 |

32-42 HRC | ||

ME SS310S |

| Sintered | 7.70 ib | 520 | 205 | 40 | 80 ~ 100 hli |

Table 3 Kev sib piv ntawm MIM thiab lwm yam txheej txheem:

Hlau txhaj molding yog ib qho tshiabhmoov metallurgy txheej txheem , nws tuaj yeem tsim cov qauv ntom ntom thiab cov saws ua ke nyuaj sumineded tsis muaj machining. Nrog rau cov yam ntxwv tshwj xeeb ntawm MIM cov ntaub ntawv, MIM muaj peev xwm tsim cov hlau precision rau ntau yam khoom, suav nrog tsheb, xov tooj ntawm tes, cov cuab yeej siv tes, cov cuab yeej kho hniav, cov cuab yeej pneumatic, cov cuab yeej hluav taws xob, cov cuab yeej phais, cov khoom ntaus pob ncaws pob thiab khoos phis tawj. Cov khoom siv hlau feem ntau siv hauv MIM txheej txheem yog stainless hlau, hlau alloy thiab cov khoom sib nqus mos.

Jiehuang MIM, peb tshwj xeeb hauv MIM qhov chaw ntawm stainless hlau, cov khoom siv hlau tsis tshua muaj hlau.

Jiehuang MIM tuaj yeem tsim precisionMIM cov khoomntawm cov khoom sib txawv raws li koj xav tau.

Tsev

Tsev